Powder Coating

Our Powder Coating process provides a robust, long-lasting finish that enhances the durability and corrosion resistance of your metal products, extending their lifespan significantly.

We offer a one-stop solution - By combining zinc electroplating with powder coating in a single facility, we reduce logistical costs and pass those savings on to our customers, providing cost-effective finishing solutions.

Committed to environmental sustainability, our powder coating operations are free from harmful solvents and volatile organic compounds (VOCs), offering you an environmentally friendly alternative to traditional liquid coatings.

Our powder coating line is capable of handling a wide range of products and sizes, from small components to large industrial parts, ensuring flexibility and versatility to meet your specific requirements.

Ready to Start Your Project?

Please fill in the form below and we will get back to you.

No project is too big or small.

BENEFITS

- The NZG powder coating process is environmentally sound, there are no volatile organic compounds contained within the powders used and excess powder is collected and recycled to minimise waste.

- The NZG Blue zinc plating process provides exceptional adhesion & corrosion protection beneath powder coatings, the combination of the two coatings achieves outstanding performance.

- Utilising state-of-the-art equipment and techniques, we deliver a smooth, high-quality finish that meets stringent industry standards.

- Custom Colour Matching: We offer a comprehensive range of colors and finishes, including custom colour matching services, to meet your specific design requirements and aesthetic preferences.

- Our efficient workflow and advanced technology allow for rapid processing, ensuring quick turnaround times without compromising on quality.

Our central UK site in Kirkby-in-Ashfield Nottinghamshire is just 5 minutes away from the M1.

"They’ve never looked better – you’ve given our shelving a new lease of life!"

A customer, and the company

OUR SERVICES

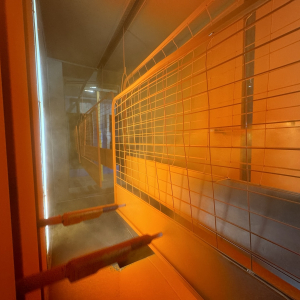

EDGE PROTECTION BARRIERS

NZG refurbishes edge protection barriers using zinc electroplating and powder coating, delivering finishes that last up to twice as long as standard coatings while reducing costs by 26–55%. Fully EN 13374 compliant with fast UK-wide turnaround.

LEARN MORE

ZINC ELECTROPLATING

Exceptional corrosion resistance, ensures your metal components stay protected against the elements. Consistent and reliable quality, backed by years of experience.

LEARN MORE

FAQS

Powder coating is a high-performance finishing process that applies a dry, electrostatically charged powder to metal surfaces. Once heat-cured, it forms a smooth, durable, and corrosion-resistant finish. At NZG, we use powder coating to protect and enhance edge protection barriers, fixings, and steel components for long-lasting performance.

Powder coating works by applying an electrostatically charged powder to a pre-treated metal surface. The powder sticks to the grounded metal and is then baked at high temperature, melting into a tough, even layer. At NZG, this process ensures superior resistance to impact, abrasion, and weathering for every coated component.

Powder coating offers superior durability, longer lifespan, and a more consistent finish compared to traditional paint. It resists chipping, fading, and corrosion while providing a wide range of colours and textures. At NZG, our powder coating process also reduces environmental impact and maintenance costs.

Yes, powder coating adheres well to zinc electroplated surfaces, the combination of the two coatings gives exceptional corrosion protection. If the powder coating is chipped or damaged, the underlying zinc electroplating prevents the steel surface from rusting and undermining the powder coating around the damaged area.

Yes, powder coating is one of the most sustainable metal finishing methods available. It contains no solvents or toxic chemicals, produces minimal waste, and allows unused powder to be recycled. NZG’s powder coating process fully complies with UK environmental regulations and supports sustainable construction practices.

Powder coating works best on conductive metal surfaces such as steel, aluminium, and iron. Non-metal materials like plastic or wood generally cannot be powder-coated because they don’t conduct electricity or withstand curing temperatures.

SUPPLIERS TO